- HOME

- PRODUCT INFORMATION

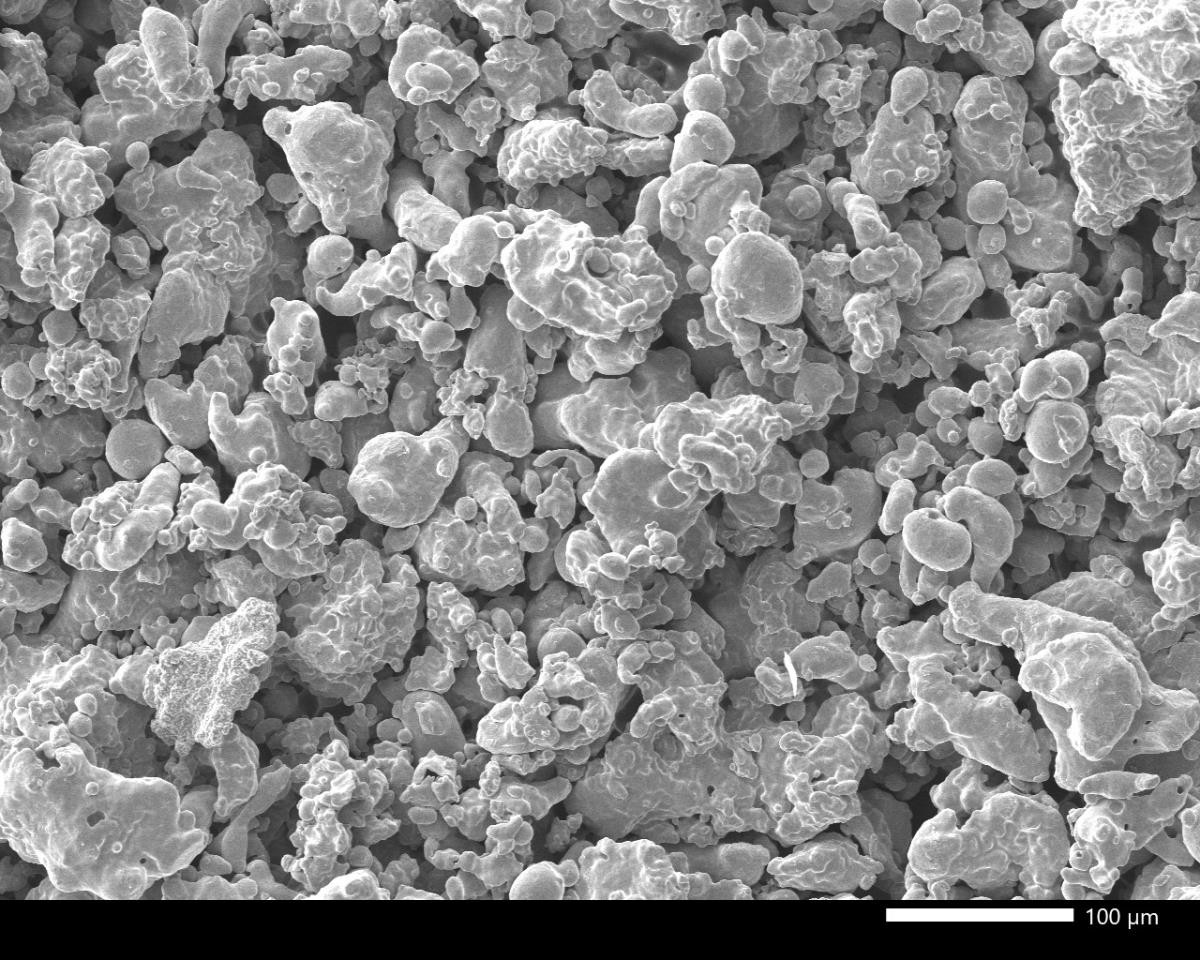

- Bronze powder

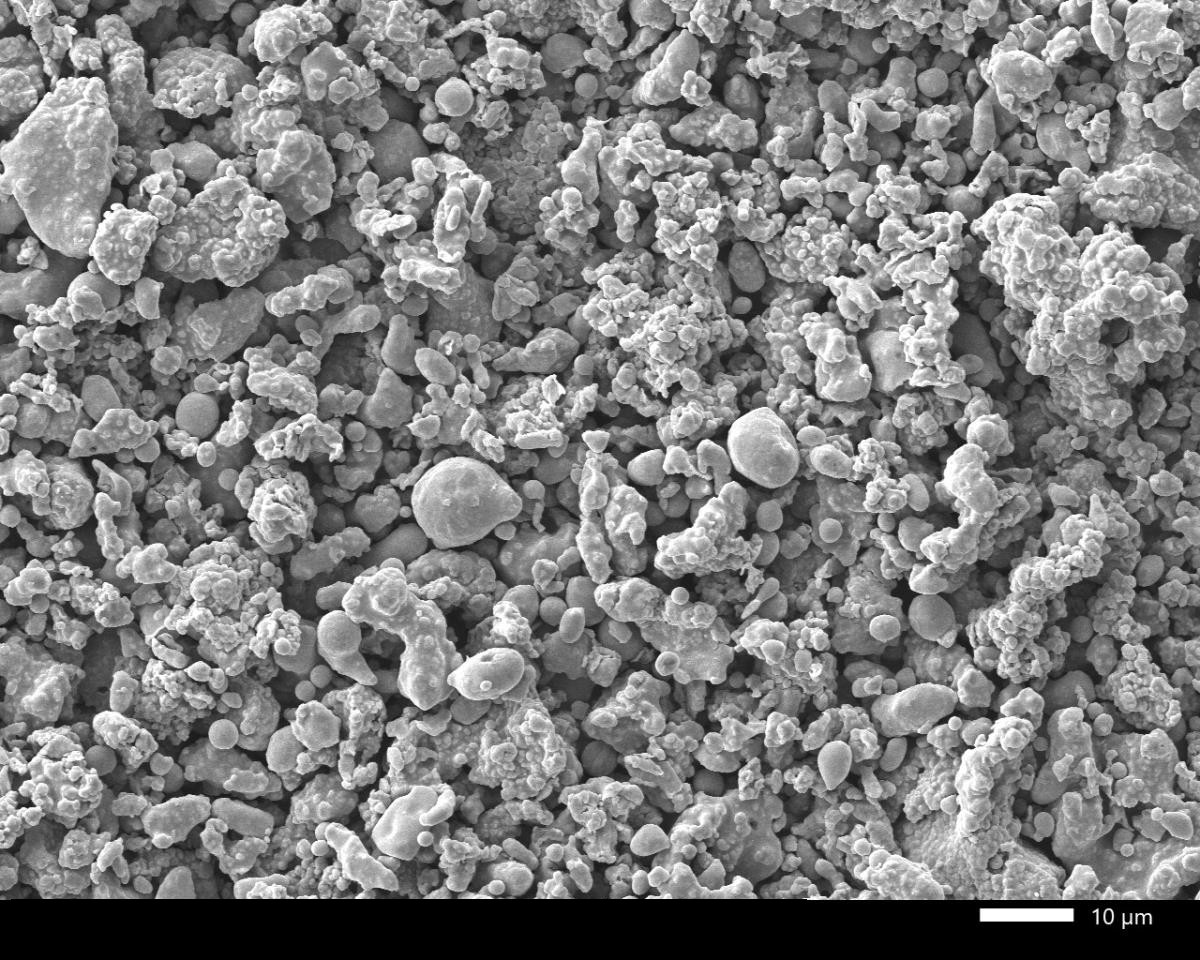

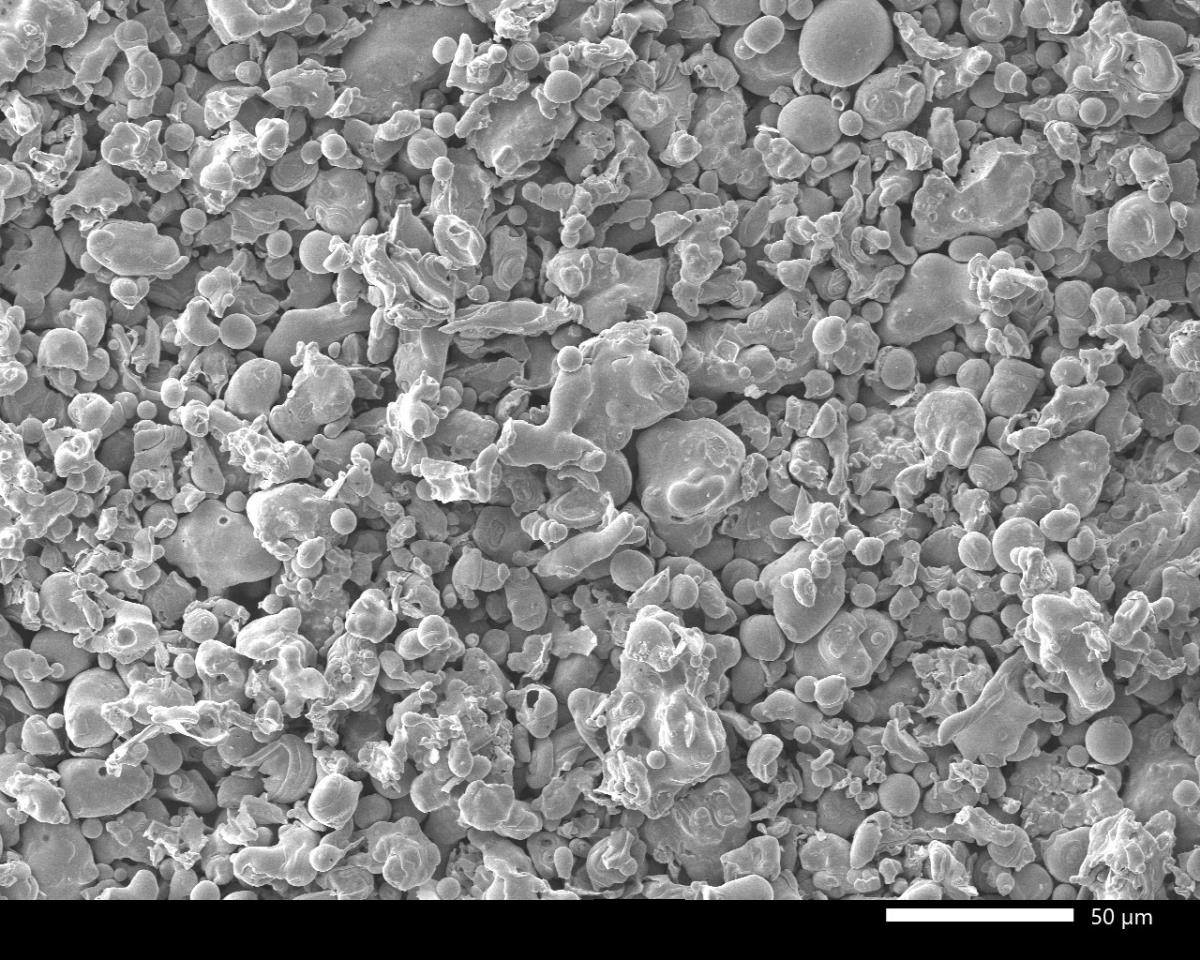

Super Fine Bronze powder

- Composition

- Copper: 90%, Tin: 10%

- Manufacturing method

- Water atomization method

- Application example

- Metal bond material for diamond tools

- Others

- Please contact us for composition and particle size.

Typical data

| Product name | Particle size |

Tap density (Mg/m³) |

Surface area (m²/g) |

Particle size distribution(by Microtrac) | Chemical composition | ||||

|---|---|---|---|---|---|---|---|---|---|

|

Accumulative 10% diameter (µm) |

Accumulative 50% diameter (µm) |

Accumulative 90% diameter (µm) |

Maximum diameter (µm) |

O (mass%) |

Sn (mass%) |

||||

| SF-BR9010 | 10µm | 3.6 | 0.3 | 4.7 | 10.6 | 19.2 | 51.9 | 0.1 | 10.3 |

| SF-BR9010 | 5µm | 3.7 | - | 2.9 | 5.5 | 9.6 | 26.2 | 0.1 | 10.3 |

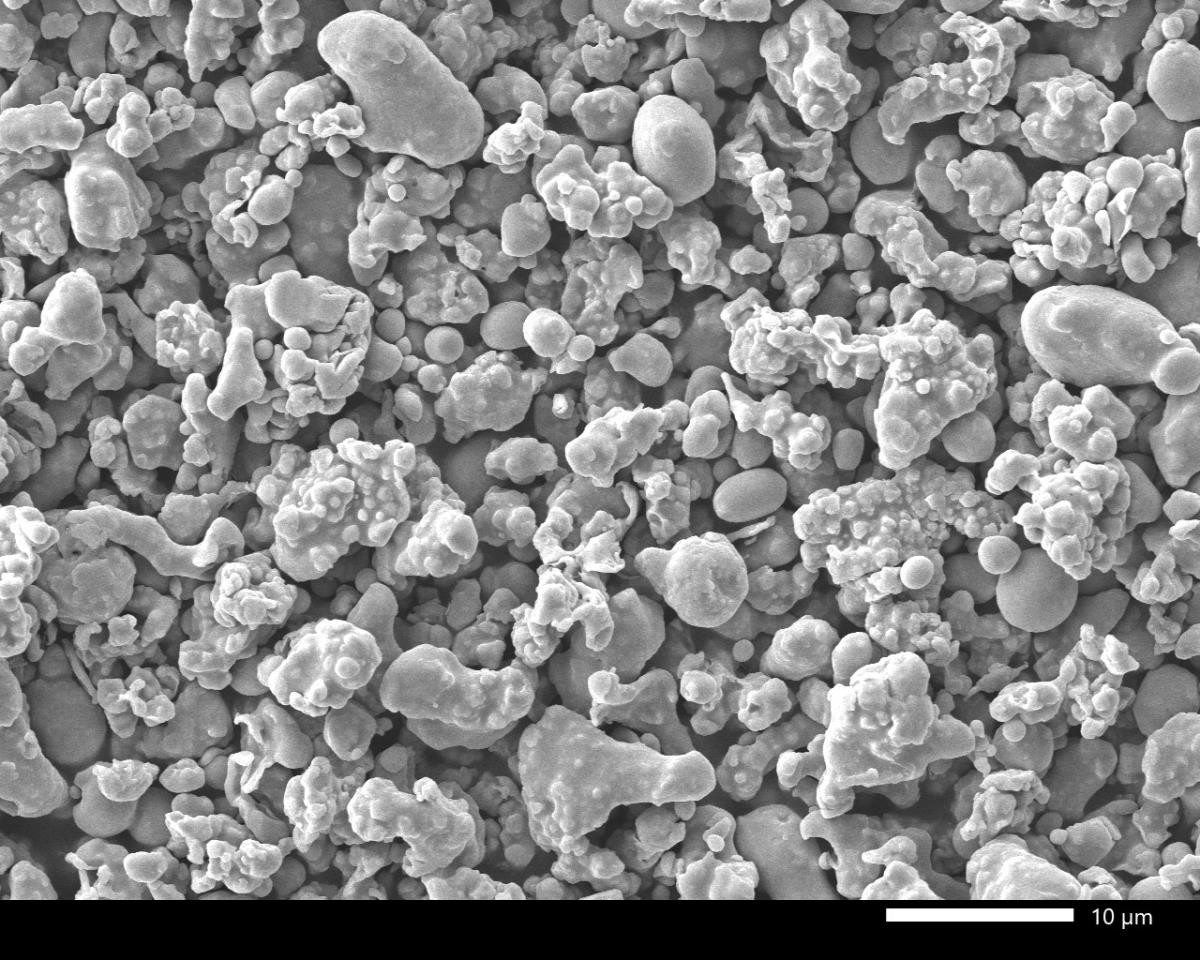

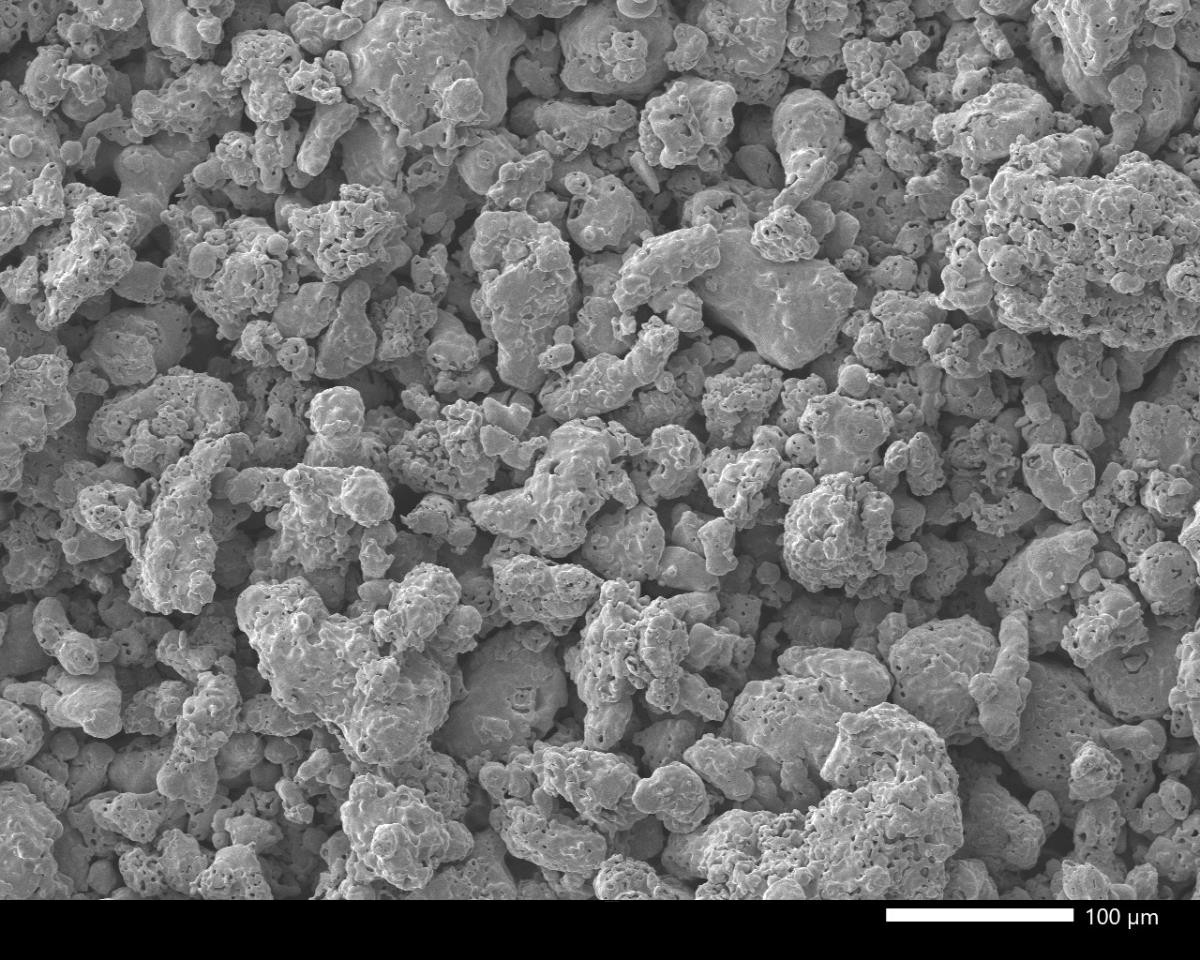

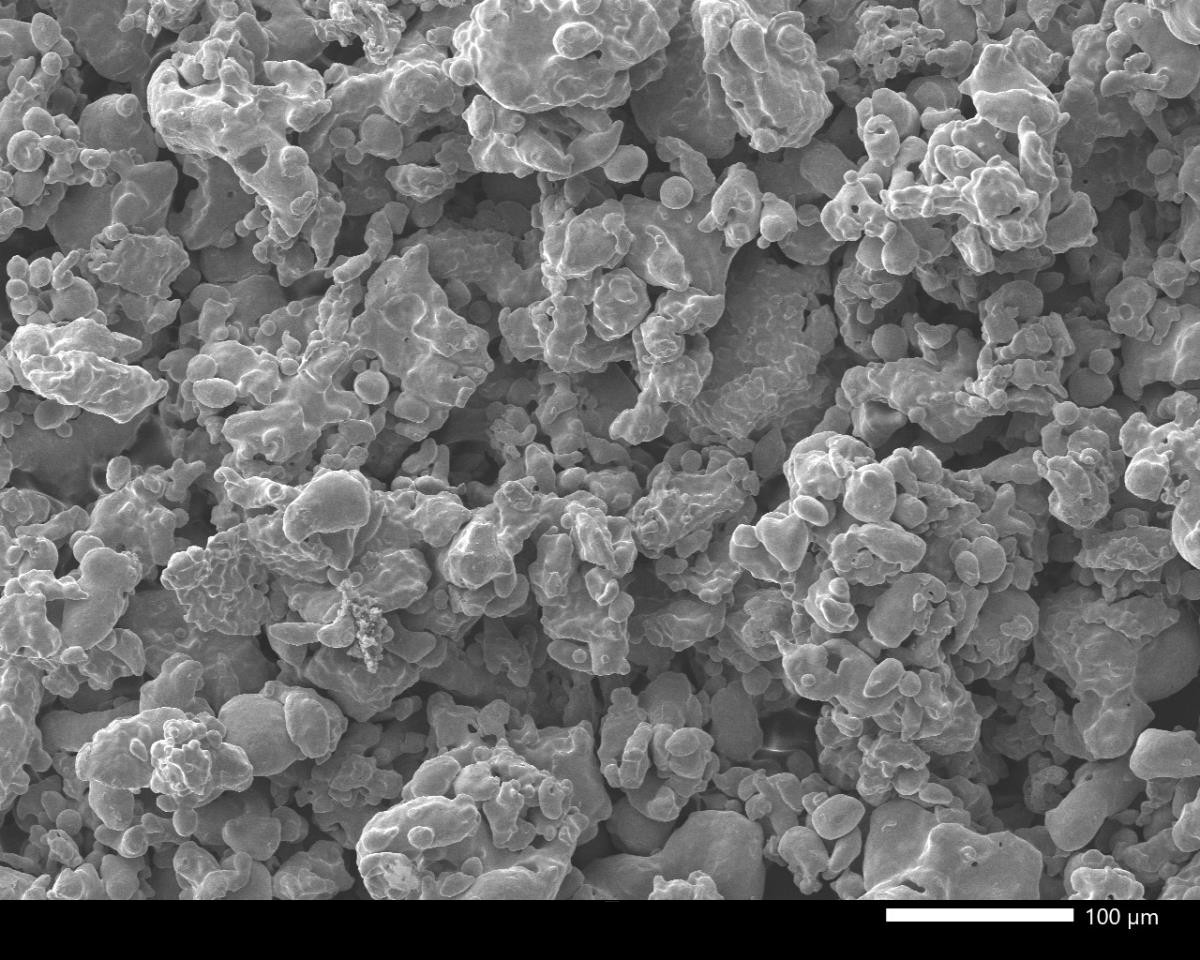

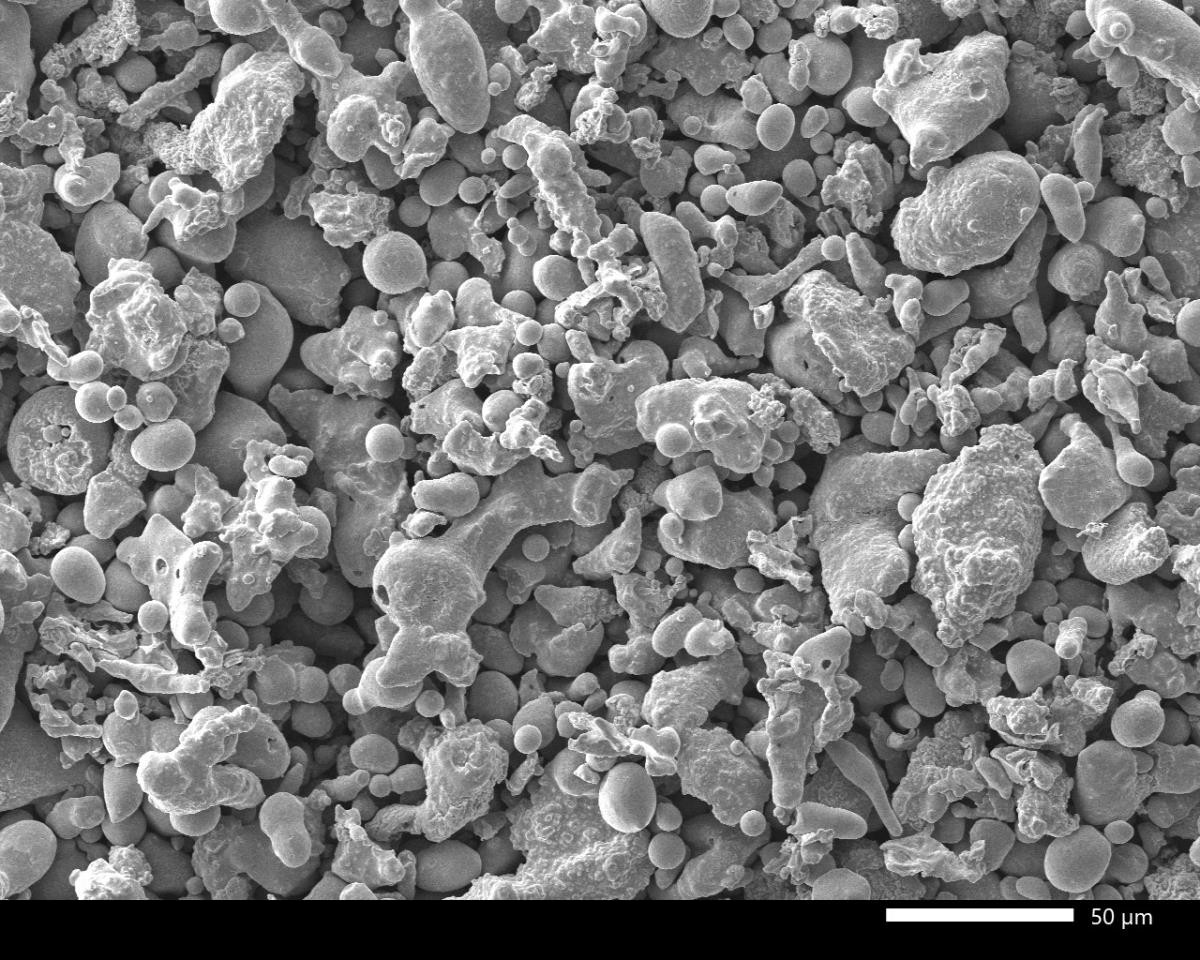

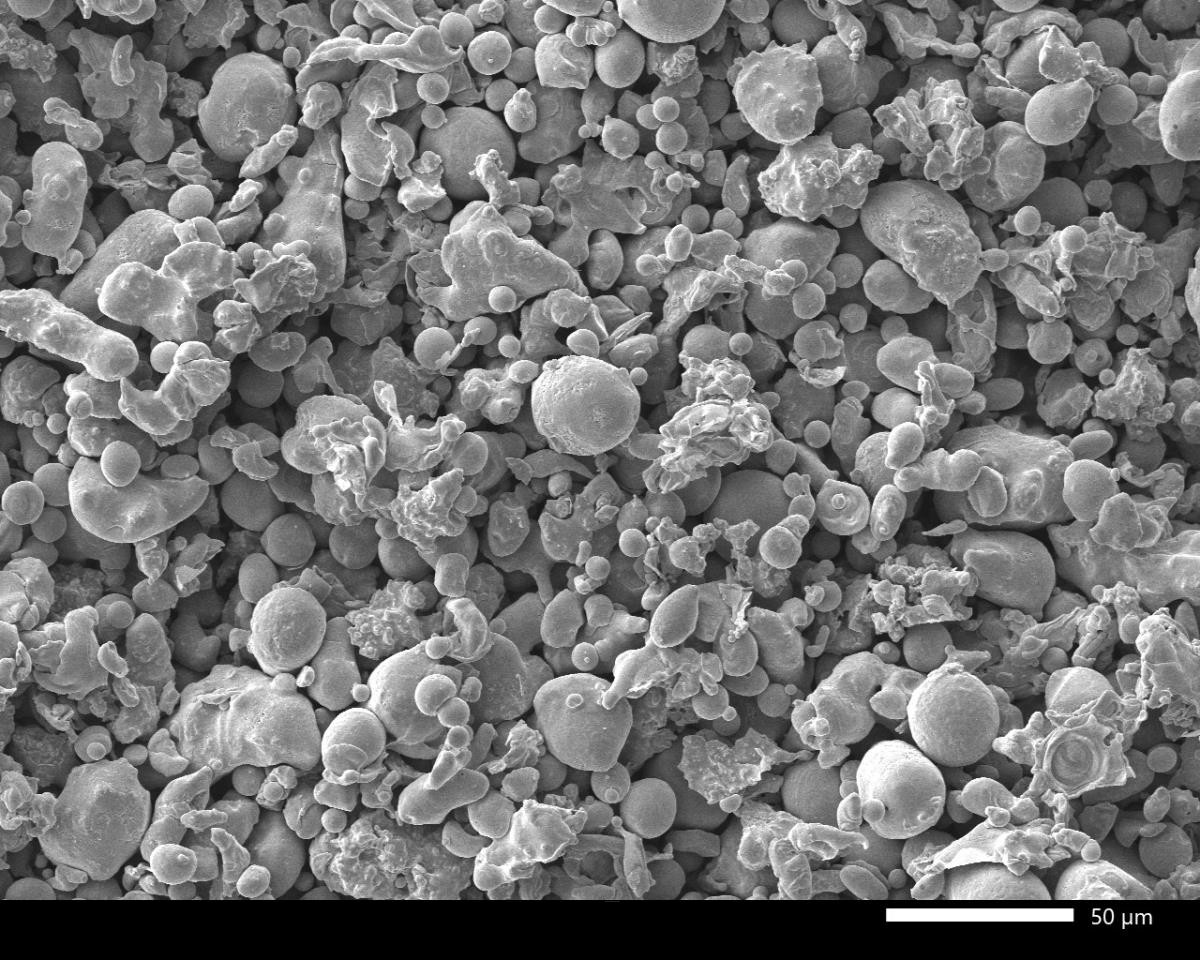

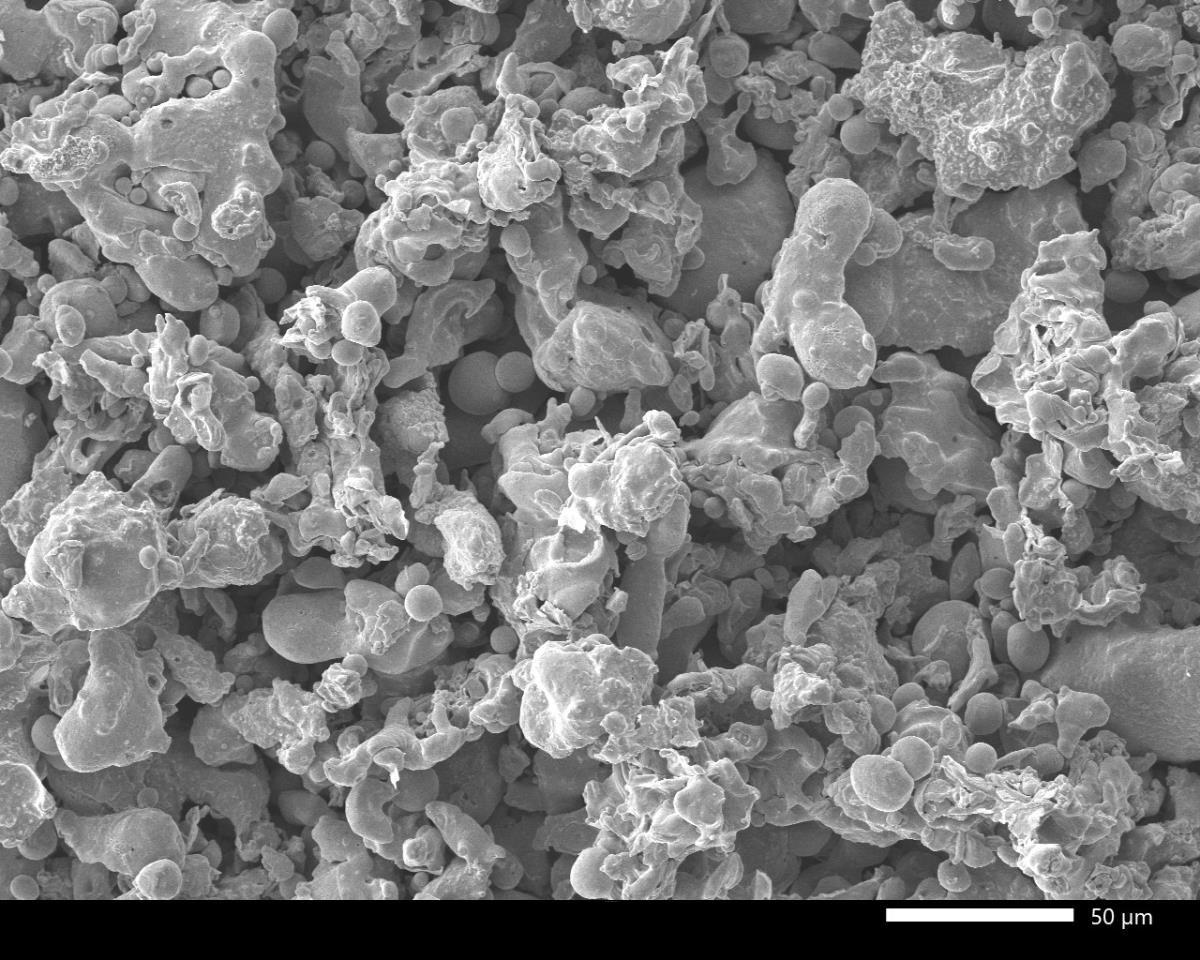

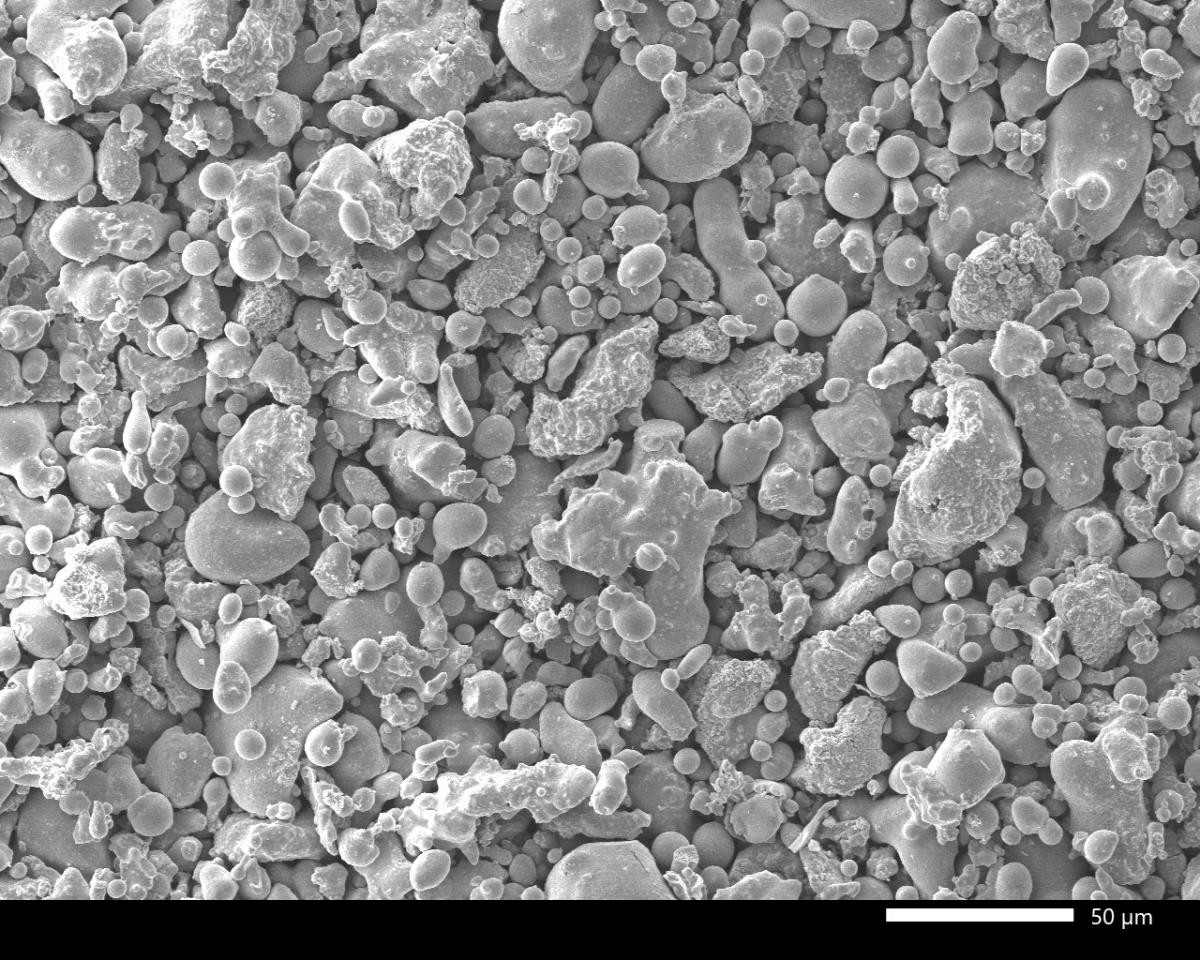

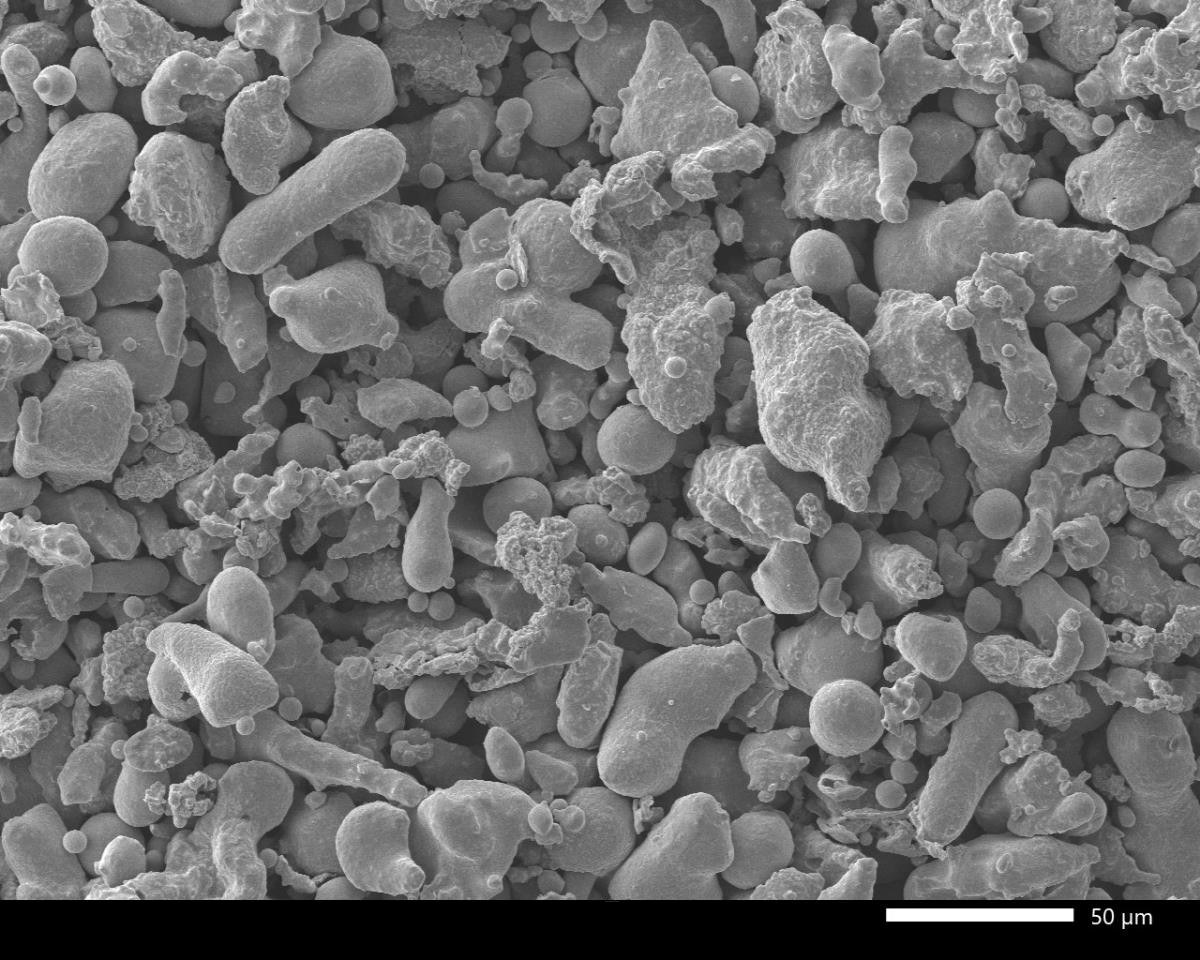

Bronze powder

- Composition

- L89 Copper: 89%, Tin: 11%

KTS, S91 Copper: 91%, Tin: 9%

S8515 Copper: 85%, Tin: 15%

S8020 Copper: 80%, Tin: 20%

S6733 Copper: 67%, Tin: 33%

S5050 Copper: 50%, Tin: 50%

PBC-2A Copper: 90%, Tin: 10%, Phosphorus: 0.3%

- Manufacturing method

- Water atomization method

- Application example

- Sintered oil-impregnated bearing (L89, PBC-2A)

Sintered machine parts (KTS, S91)

Metal bond materials for diamond tools (S8515, S8020, S6733, S5050)

Typical data

| Product name | Particle size |

Apparent density (g/cm³) |

Flow rate (s/50g) |

Particle size distribution(mass%) | Chemical composition | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| +300µm | +180µm | +150µm | +106µm | +75µm | +63µm | +45µm | -45µm |

Cu (mass%) |

Sn (mass%) |

P (mass%) |

||||

| L89 | - | 2.10~2.42 | <30 | - | <4 | <6 | 12~21 | 21~28 | 12~20 | 16~22 | 14~20 | 89 | 11 | - |

| KTS | - | 2.35~2.75 | <30 | - | <3 | <5 | 15~23 | 25~37 | 14~20 | 14~20 | 6~14 | 91 | 9 | - |

| LR-3 | - | 2.35~2.75 | <30 | - | <3 | <5 | 5~15 | 16~26 | 14~19 | 21~28 | 18~30 | 91 | 9 | - |

| S91 | -120# | 3.30~3.70 | <20 | - | <0.1 | <0.2 | 7 | 10~20 | 8~15 | 15~25 | 42~52 | 91 | 9 | - |

| S91 | -325# | 3.20~3.50 | - | - | 0 | 0 | 0 | 0 | 0 | <0.3 | >99.7 | 91 | 9 | - |

| S8515 | -325# | 2.80~3.25 | - | - | 0 | 0 | 0 | 0 | 0 | <0.3 | >99.7 | 85 | 15 | - |

| S8020 | -325# | 2.70~3.20 | - | - | 0 | 0 | 0 | 0 | 0 | <0.3 | >99.7 | 80 | 20 | - |

| S8020 | -200# | 2.50~3.10 | - | - | 0 | 0 | 0 | <0.3 | <4 | 15~25 | 70~85 | 80 | 20 | - |

| S6733 | -325# | 2.70~3.30 | - | - | 0 | 0 | 0 | 0 | 0 | <0.3 | >99.7 | 67 | 33 | - |

| S5050 | -325# | 3.20~3.70 | - | - | 0 | 0 | 0 | 0 | 0 | <0.3 | >99.7 | 50 | 50 | - |

| PBC-2A | -100# | 3.00~3.30 | <25 | - | <0.1 | <0.2 | <7 | 13~19 | 11~14 | 17~26 | 40~47 | bal. | 10 | 0.3 |

| PBC-2A | -325# | 3.10~3.40 | - | - | 0 | 0 | 0 | 0 | 0 | <0.3 | >99.7 | bal. | 10 | 0.3 |

| PBW | -200# | 3.00~3.30 | <25 | - | 0 | 0 | 0 | <0.3 | <3 | 17~26 | 70~85 | bal. | 10 | 0.3 |